The circular economy is a production and consumption model, with scope to maximize products value involving sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible, through different strategies along the whole life cycle of products. (1)

Most definitions in use have in common the principle of circularity and the goal of moving away from the traditional linear business models to more circular ones. It implies practices with the purpose of waste elimination towards zero landfill, products circulation fostering repurposing, recycle and enabling the nature to repristinate its natural cycle such as the regenerative agriculture. (2)

Circularity refers to sustainable materials management, practices that optimize resource efficiency, minimize waste across the entire production and consumption cycle, emphasizing sustainability and economic efficiency. (3)

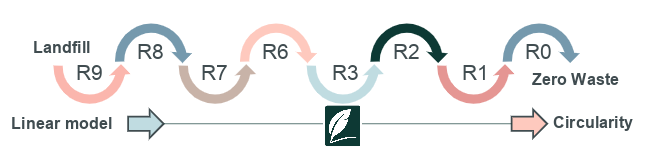

It relate, more over, to the so called R-framework that distinguish 10R strategies, which are categorized in 3 level (1) (10):

- Smarter product use and manufacture (R0 Refuse, R1 Rethink R2 Reduce);

- Expand lifespan of product and its parts (R3 Reuse, R4 Repair, R5 Refurbish, R6 Remanufacture, R7 Repurpose);

- Useful application of materials (R08 Recycle, R09 Recover).

The R strategies application analysis (from R9 to R0) through waste and materials stream mapping, setting priorities based on data, visualized with a pareto distribution impact diagram, permit to climb the ladder from linear model (landfill) to circularity (R0 Refuse) step by step. Below are summarized the most common applicable R strategies for FMCG’s food and beverages companies:

- R0 Refuse: Make product redundant by abandoning its function: refuse the multilayer plastic packaging which is not not recyclable.

- R2 Reduce: Increase efficiency in product manufacture or use by consuming fewer natural resources and materials. Example is the application of lean manufacturing, reducing the losses, water withdrawn and discharge, energy reduction strategies by implementation of best practices.

- R3 Reuse: Reuse by another consumer or rework of discarded product which is still in good condition and fulfils its original function. Example of recipe reformulation bringing reincorporation of 5-10% of reworked product.

- R7 Repurpose: Use discarded product or parts of it in a new product with a different function. Example is the usage of ashes from combustion for bricks production.

- R8 Recycle: Process materials to the same (high-grade) or lower (low grade) quality. Example recycle paper, carton, glass or plastic monolayer.

- R9 Recover: Incineration of materials with energy recovery. Example biomass for energy, such as cocoa shells for energy recovery.

Companies which commit themselves to environmental, social, and governmental (ESG) metrics, have the potential opportunity to become the leaders of the future. Circular economy within sustainability and environment zero impact presents an opportunity for organizations to gain a competitive edge (3). Yet often happens that when a company approach the circular economy from zero or at a very early stage level, see a big obstacle or confused framework.

Circular economy’s driver

The increase in demand for sustainable product is one of the most important drivers to leverage circular economy.

Regulation, infrastructure, political strategy, innovation, macroeconomic are boosting the circular economy pathway. European Union has adopted the Circular Economy Action Plan (CEAP), several countries already implemented the extended producer responsibility (EPR) under the European Responsibility Platform, allocating financial incentives to companies moving torwards a transition to circular business models. (3)

EPR mainly in the packaging side already engage significant conversation and effort. Packaging needs to be reported from suppliers in the invoice as a waste contribution cost and a tax allocated.

Directive (EU) 2018/852 is the last amendment of Directive 94/62/EC and contains updated measures designed to: prevent the production of packaging waste, and promote the reuse, recycling and other forms of recovering of packaging waste, instead of its final disposal, thus contributing to the transition towards a circular economy. (8)

Impact on Net Zero Transition

Implementing circular-economy practices empower to reduce greenhouse-gas emissions from production sites. That was the most relevant conclusion from research performed in 2018 on how low-carbon goals and circular-economy principles connect and share synergies (5).

Measuring is essential

“You can’t manage what you can’t measure.” Peter Drucker.

The EU monitoring framework on the circular economy is split into the following 5 thematic areas (4) (1):

- production and consumption

- waste management

- secondary raw materials

- competitiveness and innovation

- global sustainability and resilience

Standards

ISO 59004 provides comprehensive guidance applicable to any type of organization advocating for a circular economy model, which emphasizes the sustainable management and renewal of natural resources. (6)

Life Cycle Assessment (LCA) is a standardised methodology (ISO 14040) used to assess the environmental impacts of products and/or services throughout their life cycle, i.e. from the extraction of raw materials to the final disposal. (7)

Methodology and tool to integrate

Lean manufacturing system, provide tools, like value stream mapping, visual management, GEMBA, Keizen. Those tools enable and facilitate the deployment of circular economy. Lean principle is directly linked to the R3 Reduce strategy fostering losses elimination with consequent raw materials savings and waste reduction.

Pathway practical recommendations

Below we provide a series of recommendation and steps to deploy when you start to approach the circular economy (10):

- Mapping your waste and material stream: Ex. type of waste generated, volume and quantity, destination, cost associated.

- Identify opportunity of application of the R-Framework and define the key KPI’s using the appropriate tools.

- Benchmark and gap analysis.

- Understand the tradeoff: not all strategies apply to everyone, some can cause more impact than reducing it.

- Definition of a Circular company policy.

- Create synergies with supplier, third party partners and customers, networking is key for success.

- Set targets for the identified opportunities and KPIs.

- Build a best practices catalogue.

- Develop clear and defined roadmap.

- Implement the plan monitoring the progress.

This helps to be aware, walk into basics steps, focussing on what deliver value and what is a regulation mandatory requirement. Positioning versus common players, realize your maturity versus the circular economy world, set up the ambition in a right time horizon with a solid road map. Data driven decision is fundamental, this mean that a proper and reliable data collection is necessary for a correct mapping and monitoring of the progress.

White Cardinal did develop a rating model so called Rate Plants Circularity fast, that enable and foster decision making and help the prioritization excercise.

Articles and other documents referenced:

1 Conference of European Statisticians Guidelines for Measuring Circular Economy. Part A: Conceptual Framework, Indicators and Measurement Framework. United nations 2024. Copyright United nations.

2 What is circular economy? Ellen McArthur Foundation. © Ellen MacArthur Foundation https://www.ellenmacarthurfoundation.org/media-centre/overview

3 What is circularity, MacKinsey, 2024 – © 1996-2025 McKinsey & Company https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-is-circularity

4 European Commission: Directorate-General for Environment, Circular economy – New tool for measuring progress, Publications Office of the European Union, 2023,

5 How a ‘materials transition’ can support the net-zero agenda. By Per-Anders Enkvist, Per Klevnäs, Robert Westerdahl, and Anders Åhlén. July 20, 2022 | Article .© 1996-2025 McKinsey & Company https://www.mckinsey.com/capabilities/sustainability/our-insights/how-a-materials-transition-can-support-the-net-zero-agenda

6 ISO 59004:2024 Circular economy — Vocabulary, principles and guidance for implementation Published (Edition 1, 2024) © All Rights Reserved, ISO

7 ISO 14040:2006 describes the principles and framework for life cycle assessment (LCA) Published (Edition 2, 2006) © All Rights Reserved, ISO

8 Packaging and packaging waste directive. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=LEGISSUM:l21207

9 Reduce, Reuse, Recycle: Why All 3 R’s Are Critical to a Circular Economy by Sarah King December 13, 2022

10 R-Strategies for a Circular Economy. November 9, 2023. Larae Malooly, Tian Daphne. Circularize.

© 2025 White Cardinal. All rights reserved.

© 2025 Lean First Consulting SRL. All rights reserved.

Leave a Reply