Before embarking on the path to operational excellence, companies must first understand their current position. A well-executed maturity assessment does more than pinpoint where they stand—it also outlines the initial steps toward improvement.

Misjudging their starting point can lead to misplaced priorities and misguided investments, ultimately straining resources in the wrong areas, increasing the risk of project failure or transformation setbacks.1

The Rapid Plant Assessment (RPA) process was been described in Harvard Business Review in its May/June 2002 issue 2 and in a workbook published by Tauber Institute for global operations 3.

This lean assessment method offers a streamlined approach to evaluating the efficiency and operational effectiveness of a manufacturing process. Its primary aim is to pinpoint strengths and areas for improvement, establish performance benchmarks, and drive enhancements in productivity and efficiency—starting with the most critical gaps.

Key Features of RPA

Speed and Efficiency: The assessments can be performed quickly, typically through a brief plant tour alongside a structured evaluation process. This expedience allows for rapid identification of areas needing improvement without extensive downtime or resource allocation.

Categorical Rating System: The RPA employs a rating sheet that assesses eleven specific categories, including customer satisfaction, safety, cleanliness, inventory levels, and equipment condition. Each category is rated on a scale to quantify the assessment results.

Questionnaire for Best Practices: Accompanying the rating sheet is a questionnaire composed of yes-or-no questions related to the operational practices observed during the tour. This helps in assessing adherence to lean principles and best practices.

Visual Management: The RPA encourages observers to look for visual cues and immediate evidence of operational performance rather than relying solely on documentation or records. This aligns with the Gemba walk approach in lean practices, which focuses on observing work processes in real-time.

Outcome and Action Plan: After the assessment, the findings are compiled into a summary workbook that presents strengths, weaknesses, and prioritized action items for improvement. This serves as a roadmap for operational enhancements.

Benefits of Implementing RPA4

Benchmarking: It provides a basis for comparing performance within the company and against industry standards, highlighting areas for operational excellence.

Resource Allocation: The assessment identifies critical areas that require immediate attention, allowing for effective resource management and prioritization of improvement efforts.

Continuous Improvement: Regular assessments using RPA can help organizations track progress in their lean transformation journey, ensuring ongoing optimization of processes and practices.

Applications of RPA: The methodology can be utilized not only for internal audits but also for evaluating suppliers, vertical operation structure, assessing potential acquisition targets, and overall operational check-ups. Its flexibility and historical success across numerous industries underscore its effectiveness as a diagnostic tool for optimizing manufacturing operations.

The 11 categories2,3:

1- Customer satisfaction.

2- Safety, environment, cleanliness, & order.

3- Visual Management System.

4- Scheduling system.

5- Space use, material movement, & product flow.

6- Inventory & WIP levels.

7- Teamwork & motivation.

8- Condition & maintenance of tools & equipment.

9- Management of complexity & variability.

10- Supply Chain Integration.

11- Commitment to quality.

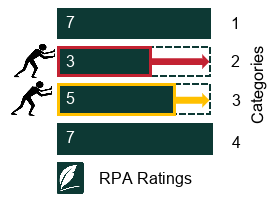

Raise the lowest rating first.

The RPA process rates an operation’s leanness based on a quick plant tour, rating each of the 11 categories on a scale from “poor” (1) to “excellent” (9) to “best in class” (11). “Best in class” is meant literally: Only one plant in each industry, worldwide, deserves this rating. Then total the ratings its calculated1. The questionnaire is completed by rating the operation by the team just after the tour.

RPA it is not a substitute of a due diligence in an acquisition process and it is one factor to consider when assessing a company. RPA should be considered as a first tool to identify the priorities to tackle in a rapid initial assessment.

Important general principles to follow1:

1- The evaluation should be conducted by an independent team, ideally a third-party entity.

2- The evaluation needs to be done where the work happens at the shop floor, or the core, practicing the GEMBA walk during the assessment.

3- The assessment must consider the external and internal factors influencing the site under review.

4- Check whether the business has a specific problem to be solved in an area, rather than verifying the presence of productivity-enhancing tools.

5- The final delivery of the assessment is an actionable improvements, roadmap, not just a measure existing performance.

6- Involve assessors in the execution that follows their evaluation.

The importance of going to the shop floor—or ‘the core’—is often underestimated. According to genchi genbutsu, a key principle of the Toyota Production System meaning ‘go and see for yourself,’ this practice, also called a GEMBA walk, provides powerful eye-brain insights.

The roadmap should be structured applying a Tactical Implementation Plan (TIP) to guide organizations through change management and operational improvements5.

Companies can only make rapid, sustainable improvements to their performance if they know exactly what to do next.

White Cardinal can assist in customize your assessment and execute it empowering the local team.

References:

1- Deployment models: How mature are your operational practices? Ron Fardell, Nils Müller, Peter Odenwälder, and Rainer Ulrich © 1996-2025 McKinsey & Company https://www.mckinsey.com/capabilities/operations/our-insights/deployment-models-how-mature-are-your-operational-practices

2- Read a Plant-Fast by R. Eugene Goodson From the Magazine (May 2002) https://hbr.org/2002/05/read-a-plant-fast

3- Rate Lean: Fast. R. Eugene Goodson. Tauber Institute for global operations. Copryright 2017 University of Michigan. http://tauber.umich.edu/research/rpa

4- Rapid Plant Assessment: Quick Rating of Operations Maturity. Rapid Plant Assessment: Quick Rating of Operations Maturity

5- The Tactical Implementation Plan (TIP) – A road map for Change Management Success. SixSigma. Blog: TIP – A Road Map for Change Management Success | LSS

© 2025 White Cardinal. All rights reserved.

Leave a Reply