Decarbonizing the global energy system requires an integrated approach—one that informs optimal infrastructure developments in a timely manner while supporting systemic changes toward energy systems predominantly supplied by variable renewable energy.

To meet the 1.5°C climate target by 2050, projections indicate:

- A fivefold increase in total renewable energy supply.

- A twofold increase in total electricity demand.

These shifts, combined with the rising share of renewables and electrification, will significantly increase the complexity of the energy system. Integrated planning is therefore essential to ensure a cost-optimized and timely energy transition.

TES: Turning Waste Heat into a Resource

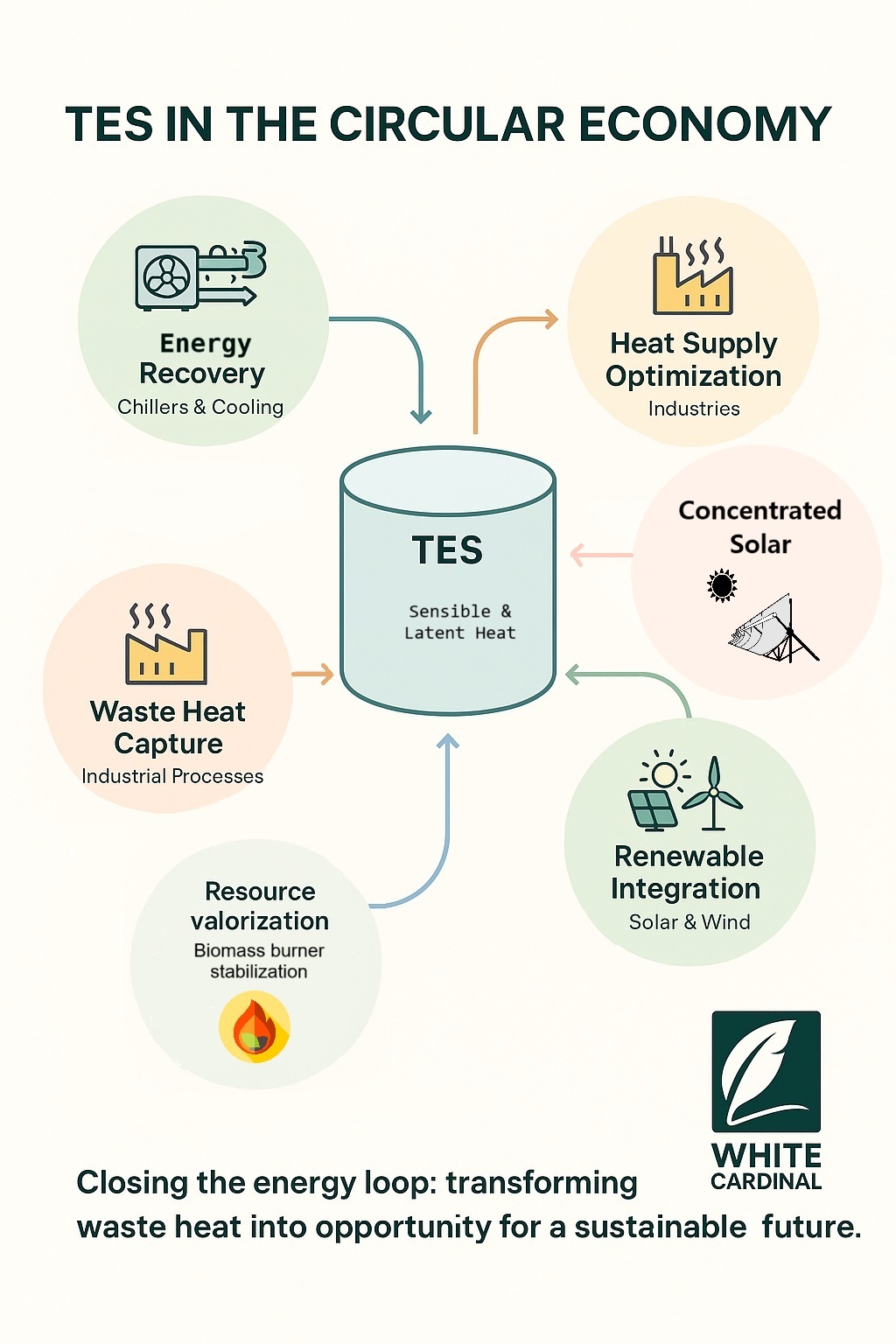

Thermal Energy Storage (TES) is more than a decarbonization technology — it is a circular economy enabler.

By capturing, storing, and reusing waste heat that would otherwise be lost, TES transforms a by-product into a valuable energy input, reducing reliance on primary energy sources.

Key benefits include:

- Integrating variable renewable energy into stable, continuous heat supply.

- Valorizing waste heat from industrial processes, turning energy losses into cost savings.

- Optimizing process efficiency by shifting heat availability to match demand.

TES system efficiencies exceed 95% (electric → TES → heat), making heat storage more cost-effective than storing electricity for later conversion. Coupling an electric boiler with TES the levelized cost of steam can be $30–$60/MWh. (1)

Coupling an heat pumps with TES the levelized cost of steam can be $15–$25/MWh. (1)

Circular & Sustainable Business Cases

TES projects can deliver internal rates of return (IRR) of 16–28%, driven by (1):

- On-site, behind-the-meter installations reducing dependence on external energy markets.

- Access to captive renewables or waste heat streams.

- Favorable market conditions (low grid fees, flexibility remuneration).

Real-world examples include (1):

- Food industry heating supplied by a peaker plant → up to 16% IRR.

- Co-generation in off-grid greenhouses → up to 22% IRR.

- Behind-the-meter renewable + TES → commercially viable regardless of market context.

Pipeline initiatives indicate CAPEX savings of at least 10%, highlighting TES as both an environmental and financial win.

Implementation Pathways

A recommended approach is to integrate TES solutions into the “Roadmap initiative pipeline” through:

- Heat-as-a-Service (HaaS) models—15-year contracts managed by energy distributors.

- Direct project management by the company in contexts where HaaS is not feasible.

Available TES Technologies for Circular Energy Systems

Thermal Energy Storage (TES) solutions can be categorized according to the heat storage principle and the operational temperature range. Two key categories—sensible heat storage and latent heat storage—offer complementary advantages for integrating variable renewable energy, improving process efficiency, and valorizing waste heat.

1. Sensible Heat Storage

Stores energy by raising the temperature of a solid or liquid medium without changing its phase. Suitable for medium to high temperature applications.

Examples:

- Water Buffers: Hot water tanks for district heating or industrial processes, enabling stable supply during peak demand.

- High-Temperature Sensible Heat: Stores energy by heating a medium such as molten salts, ceramics, steel, or concrete blocks without phase change. Operates typically above 200 °C up to 1500 °C, making it ideal for industrial processes, renewable integration, and hybrid heat-power applications.

- Examples of Technologies & Producers:

- Molten Salt Systems – Used with electricity, from grid or renewable and concentrated solar power (CSP) plants. Examples: Kyoto Group (Norway) ,TSK Flagsol (Spain), BrightSource Energy (USA), Malta Inc. (USA).

- Refractory Brick Storage – Rondo Energy (USA) uses refractory bricks to store heat up for industrial processes.

- Recycled Material Thermal Blocks – Kraftblock (Germany) produces storage units from recycled materials for large-scale, long-duration heat supply.

- Steel-Based Thermal Batteries – Lumenion (Germany) builds steel-mass storage delivering both industrial heat and electricity.

- Carbon Block Thermal Batteries – Antora Energy (USA) uses electrically heated carbon blocks for heat and power.

- Ceramic Media Regenerators – Kelvion and MAN Energy Solutions integrate ceramic-based storage for high-temperature flue gas and process heat.

- Graphite-Thermal Storage – E2S Power (Switzerland) from electiricity to steam.

- Chilled antifreeze Thermal Systems – Malta Inc. (USA)

- Crushed rocks-Based Storage – Brenmiller Energy (Israel) combines crushed rock storage with steam generation, suitable to connect with biogas burner.

- Concrete-Based Thermal Batteries – EnergyNest (Norway) uses a proprietary concrete composite (Heatcrete®) based on the concept steam to generate steam.

- Examples of Technologies & Producers:

Circular Opportunity: Enables renewable electricity, waste heat, biomass boilers or solar thermal plants at optimal load to charge thermal batteries at constant load, releasing heat on demand and cutting fossil fuel use during peaks. Many of these technologies use recycled materials or retrofit existing infrastructure, reducing the environmental footprint of deployment.

2. Latent Heat Storage

Stores heat during a material’s phase change (solid–liquid or liquid–gas), offering high energy density at a constant temperature. Particularly suited for capturing and reusing low-grade waste heat.

Examples:

- Steam Accumulator: Pressurized steam reservoirs that decouple steam production from consumption, smoothing process fluctuations.

- Phase Change Materials (PCMs): Used to recover cooling energy from chillers, refrigeration systems, or cold storage facilities.

- Cold TES Systems: Capture surplus cooling during low demand periods and release it during peak cooling demand.

- Latent Heat Tanks for Industrial Cooling: Integrated with chillers and compressors to allow constant-load operation, improving efficiency and lifespan.

Circular Opportunity: Turns unavoidable low-grade waste heat or cold into a usable energy resource, reducing the need for additional primary energy input.

3. Technology Screening Methodology:

To identify the most suitable TES solutions for specific applications, a structured screening methodology is essential. The following criteria allow decision-makers to assess both technical feasibility and commercial viability, while considering operational context and circular economy potential—particularly in maximizing waste heat valorization.

Key screening factors include:

- Temperature of Discharge (°C) – Matching output temperature to application requirements (industrial heat, district heating, cooling, etc.).

- Footprint – Physical space required for installation relative to site constraints.

- Storage Density (MWh/m²) – Energy stored per unit area, influencing land use efficiency.

- Efficiency (%) – Conversion and recovery efficiency from charging to discharging.

- Safety – Operational and environmental safety of the storage medium and system.

- Operating Experience – Track record of successful deployments in relevant sectors.

- Durability (years) – Expected operational lifespan before significant refurbishment.

- Maintenance – Frequency and complexity of service interventions.

- Capital Expenditure (CapEx) – Initial investment cost.

- Operational Expenditure (OpEx) – Ongoing operating and maintenance costs.

- Levelized Cost of Energy (LCOE) – Total lifecycle cost per unit of delivered energy.

- Market Readiness Level (TRL & MRL) – Maturity of the technology and supply chain.

This framework ensures that technology choices are not only technically sound but also economically sustainable, scalable, and aligned with long-term decarbonization targets.

TES as a Circular Economy Catalyst

TES embodies circular economy principles in the energy sector by:

- Closing the loop on industrial heat losses.

- Maximizing renewable utilization and avoiding curtailment.

- Reducing infrastructure demand through efficiency gains.

- Lowering carbon intensity without proportionally increasing CAPEX.

In this sense, TES doesn’t just support the energy transition — it reshapes it into a regenerative system where waste becomes value.

Conclusion

Thermal Energy Storage enables industries to:

- Decarbonize heat supply.

- Valorize waste heat streams.

- Reduce costs while increasing efficiency.

- Align with both net-zero targets and circular economy strategies.

By bridging renewable variability with continuous heat demand, TES positions itself as a strategic, resource-smart solution — transforming energy waste into opportunity.

How we can support

- Screen technology customized in function of the industrial context

- Provide business cases customized

- Bring in contact with producer and energy distribution

- Support in the project development

References:

- Net-zero heat: Long Duration Energy Storage to accelerate energy system decarbonization |LDES Council, McKinsey & Company

- Di Ibrahim Dinçer, Marc A. Rosen, Thermal Energy Storage: Systems and Applications , 2021 (p39)

- Maria Elena Navarro Rivero, Thermal energy storage options, Power Generation Technologies for

- Low-Temperature and Distributed Heat, Woodhead Publishing Series in Energy, 2023, Pages 419-471

- Roelofsen, O., Somers, K., Speelman, E. and Witteveen, M., Plugging in: What electrification can do for industry, McKinsey & Co., May 2020.

© 2025 White Cardinal. All rights reserved.

Leave a Reply